Custom drawstring backpacks show up everywhere these days. From gym sessions to trade shows, they carry stuff with ease.

But picking the right material, like 210D polyester drawstring backpack or non woven drawstring bag, makes a huge difference. Get it wrong, and the bag falls apart fast. Let’s dive in.

Why Material Choice Matters for Custom Drawstring Backpacks

Material picks shape how drawstring backpacks perform. Best material for drawstring backpacks depends on the job. Choose material for custom drawstring bag wisely, or face issues.

They might look similar, but materials affect durability, water resistance, costs, eco-friendliness, and how long the brand stays visible. Typical headaches include bags tearing on event day or fuzzing up. Rain soaks through, wetting files and clothes inside. Logos peel off or fade quick. Users think it’s cheap and toss it after one go.

As manufacturers like Raincoat Gift see in real projects, the same design printed on 210D polyester and non-woven PP can lead to very different user experiences and brand impressions.

What Exactly Is 210D Polyester and Non-Woven PP?

Materials vary in makeup and use. 210D polyester brings strength from its weave. Non-woven polypropylene offers quick production for basics.

210D Polyester: Structure, Coatings, and Key Properties

What is 210D polyester? It’s a fabric with denier rating. 210D means 9,000 meters of yarn weigh 210 grams. Light yet sturdy. Coatings like PU, PVC, or silver glue boost waterproofing, stiffness, and price points.

210D fabric for bags fits well. Think drawstring packs, lightweight backpacks, rain covers, tent linings.

Non-Woven Polypropylene: How It’s Made and Where It’s Used

What is non woven polypropylene fabric? It forms through melt-blown or spunbond processes. Fibers bond with heat, no traditional weaving. Weights range from 70 to 100 gsm for promo bags. Feels papery or cloth-like.

Common spots include grocery totes, disposable eco-bags, big promo giveaways.

210D Polyester vs Non-Woven: Head-to-Head Comparison for Drawstring Backpacks

210d polyester vs non-woven sparks debates. Compare materials for drawstring backpacks to spot winners for specific needs.

Durability and Load Capacity

210D holds up with its woven structure plus PU coating. Handles medium loads like gym clothes, shoes, books. Non-woven suits light stuff, papers, brochures. Heavy use leads to pilling or rips over time.

Ever notice how some bags last seasons while others shred after a week? That’s the weave talking.

Water Resistance and Weather Protection

210D with PU hits 1000 to 2000mm hydrostatic head. Stands up to light or moderate rain. Great for outdoor gigs or commutes. Non-woven lacks real waterproofing. Mostly splash-resistant at best.

Look, Feel and Brand Perception

210D has subtle texture. Colors pop, printing shines. Gives off a sporty, outdoor gear vibe. Non-woven resembles eco-shopping bags. Creases show, ages fast.

For brands, 210D acts as long-term ad space. Non-woven feels like one-off promo swag.

In some campaigns produced by Raincoat Gift, clients switched from non-woven PP to 210D polyester for sports events, and noticed that attendees kept using the bags months after the event, extending brand exposure.

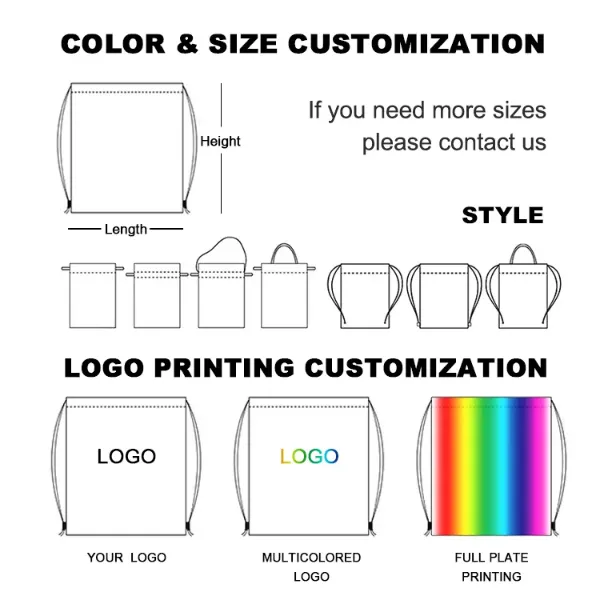

Printability and Customization

Both work for screen printing. 210D excels in heat transfer, digital prints, gradients. Colors stay bright, wash well.

Non-woven nails solid colors or simple logos cost-effectively. Complex designs look okay, but not stellar.

Cost, MOQ and Shipping Weight

Non-woven costs less per unit. Ideal for thousands in big promos. 210D runs higher but lasts longer, looks premium. Suits quality-focused events. Shipping? Lighter non-woven saves on bulk hauls.

Sustainability and Real-World Reuse

Non-woven PP reuses possible, but often treated as disposable. Recycling options limited. 210D polyester from petroleum, yet durable. RPET 210D with water-based PU cuts carbon impact.

Think reuse counts. A 210D bag lasting six months versus non-woven ditched after two or three uses. Which harms less?

Which Material Fits Which Project? Use-Case Scenarios

Scenarios guide picks. 210d polyester drawstring bag for sports? Often yes. Non woven drawstring bags for promotions? Spot on.

Large-Scale Promotions and Trade Shows

Budget tight, giveaways plenty? Go non-woven with basic logos. For eco-leaning brands, try RPET non-woven or RPET 210D.

Sports, Outdoor Events and Rainy-Day Giveaways

Need waterproof, tough, bit more load? 210D polyester shines. Think gyms, school teams, marathons, festivals. Rain hits, and non-woven flops.

Schools, Teams and Daily Commute

Daily hauls for books or shoes? Pick 210D or higher denier polyester. Non-woven better for one-time packs with handouts or docs.

If your project mixes different use cases, manufacturers like Raincoat Gift often suggest a tiered approach: 210D polyester drawstring backpacks for VIPs or staff, and non-woven versions for mass giveaways.

A Practical Checklist for Buyers: 210D or Non-Woven?

How to choose 210d or non woven drawstring bag? Use this drawstring backpack material checklist.

- Event type and how often used.

- Target crowd: students, athletes, conference folks.

- Expected weight inside, plus rain or outdoor exposure.

- Brand image: upscale feel, everyday vibe, or pure green.

- Budget cap and price range per unit.

- Eco certs needed? RPET, recyclables mentioned?

Share this list with suppliers, like Raincoat Gift OEM factories. Speeds talks, cuts samples.

There Is No “Best” Material, Only the Best Fit

210d polyester or non woven which is better? Depends. For max value in one-shot big promos, non-woven drawstring packs make sense. Aiming for lasting brand buzz, sporty or rainy scenes, better user vibes? 210D polyester drawstring backpacks win.

Pro picks start with clear uses, budgets, green goals. Skip chasing cheapest or greenest sounding without thought.

FAQ

Q: Is 210D polyester better than non-woven fabric for drawstring bags?

210D polyester is generally more durable, water-resistant, and long-lasting, making it better for sports, outdoor events, and daily use. Non-woven fabric is more cost-effective for large giveaways.

Q: What is the difference between 210D polyester and non-woven polypropylene?

210D polyester is a woven fabric with higher strength, better tear resistance, and improved print quality. Non-woven polypropylene is lightweight, inexpensive, and suitable for short-term promotional bags.

Q: Which material is more suitable for custom logo printing?

Both materials support screen printing, but 210D polyester offers better results for heat transfer, full-color designs, and detailed logos due to its smoother surface and coating options.

Q: Are non-woven drawstring bags waterproof?

Most non-woven polypropylene bags are not fully waterproof. They resist light moisture but cannot protect items in rain. 210D polyester with PU or PVC coating provides much better water resistance.

Q: Which drawstring bag material is more eco-friendly?

Non-woven PP is often marketed as recyclable, but real-world reuse is limited. 210D polyester lasts longer and can be made with RPET for better sustainability through extended use and reduced waste.